Elm activates new Robotic Buffing Cell at Chemetal in Easthampton

By Mike Holmberg

2023 was a great year for Automation. The engineering business unit was involved with projects that ranged from making golf balls to boxing gourmet muffins.

2024 looks to bring us many new opportunities and we look forward to helping our customers solve their automation needs this year. We just completed an existing project at Chemetal in Easthampton — a Robotic Buffing Cell.

Chemetal was looking for a way to eliminate the tedious and strenuous working environment for their operational staff and means to control the dust in the manufacturing area where they produce custom brushed aluminum decorative panels for a wide array of applications.

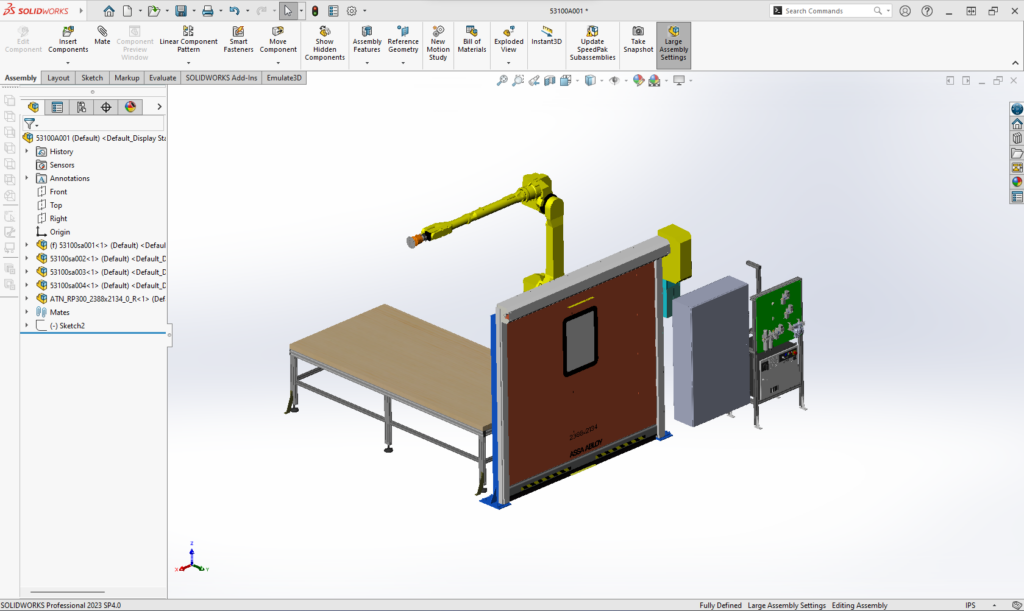

We began this project by developing some 3D virtual simulations for the concept to illustrate to Chemetal how the system would function within their facility.

We then developed a prototype at Falcon Drive to test the buffing tool with one of our smaller collaborative robots. This allowed us to work with Chemetal to experiment with the buffing process and refine the solution to produce acceptable product.

We then built the final system and performed a Factory Acceptance Test at Falcon Drive prior to deploying the system at Chemetal.

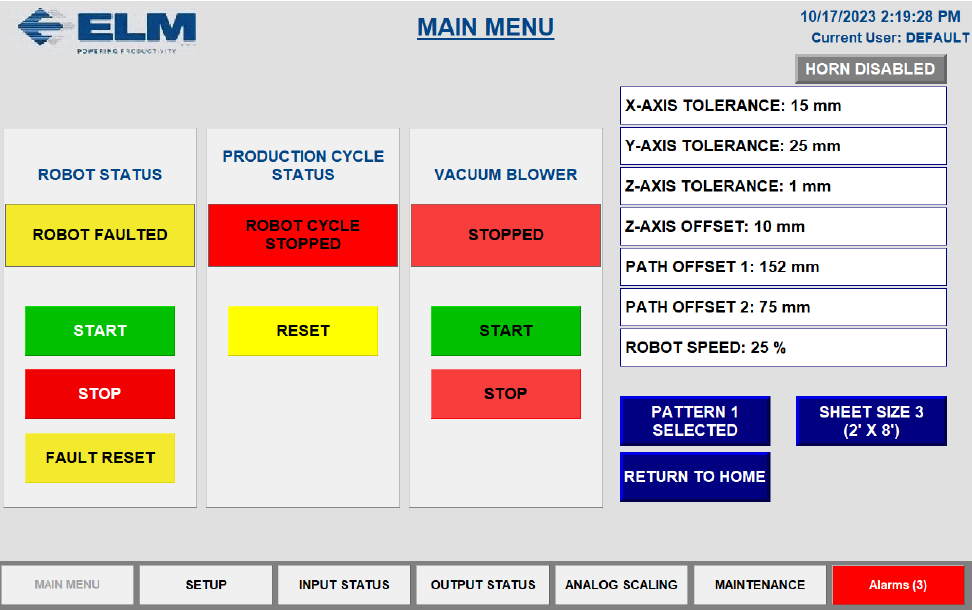

This system is now up and running and has eliminated a dirty and strenuous task for their operators (as seen below) and allows them to now manage and run the new robotic cell.